Product Detail

Product Tags

Overview

Essential details

- Warranty:

-

1 year

- Place of Origin:

-

China

- Brand Name:

-

evergear

- Model Number:

-

EK

- Type:

-

HELICAL BEVEL GEAR

- Frequency:

-

50HZ

- Phase:

-

Three-phase

- Protect Feature:

-

ip55

- AC Voltage:

-

230/400 400/690V

- Efficiency:

-

IE1 IE2 IE3 IE4

EK Helical-bevel gearmotors

EK series helical-bevel gear units: high degree of efficiency and gearing with high fatigue strength

The figure shows a gearmotor with a helical-bevel gear unitThe compact design of all our gear units is most obvious in our helical-bevel gear units. This property is particularly

interesting, for example, for machine applications with limited space available. Here, you need powerful drive technology with a compact design. This is just the right environment for our helical-bevel gear units with a torque range from 80 to 50,000 Nm.

With their high efficiency in both directions of rotation and at any input speed, these right-angle gear units are very

energy-efficient. Their high-endurance gearing is wear-free and lasts a gear unit's lifetime. For precise positioning tasks, you can use the K series gear units with reduced backlash.

in our portfolio: sizes K..39 and K..49 complete our range of two-stage helical-bevel gear units. They set the standards together with sizes K..19 and K..29: four sizes allow for torques from 80 Nm to 500 Nm.

Only half the solution without a motor? Then use our modular concept and combine the gear units of the K series with an AC motor to a compact gearmotor or with a servomotor to of your choice. Or simply choose the separate AC motor or Servo motor that meets your requirements.

EK Helical-bevel gearmotors

Our helical-bevel gearmotors EK..are an excellent choice for many applications that require compact drives with high efficiency.

As they are especially low-maintenance they will reduce your costs in day-to-day operation.

EK Helical-bevel gearmotors: low-maintenance and high efficiency

Helical-bevel gearmotors EK..Are you looking for a low-maintenance and largely wear-free but high torque drive solution? Then you are making the right decision with our helical-bevel gearmotors EK… This is because we offer you gear units and motors combined as compact drive components: perfectly in tune with each other and adapted to your application.

Due to their design, our helical-bevel gear units are especially robust and low-maintenance. The reason for this is the

high-endurance gearing and the high manufacturing quality of all component parts. Combine this helical-bevel gear unit with an AC motor and you get a powerful and compact helical-bevel gearmotor: with high efficiency and, depending on the energy efficiency class required, with a motor power range of up to 200 kW.

Irrespective of the application you wish to implement, the combination options for helical-bevel gear units EK… are diverse:

wide range of gear unit ratios, foot or flange-mounted design for flexible installation and motor variants for energy efficiency classes IE1 to IE4.

Save time and money

By opting for one of our gearmotors, you are already saving time and money with this selection and project planning. This is because our modular system enables a multitude of combination options for gear units and motors. You can therefore reduce operating costs, count on a long service life and benefit from simplified maintenance that is characteristic of our brand.

EK Helical-bevel gearmotors

Energy-efficiency

Wide range ratio

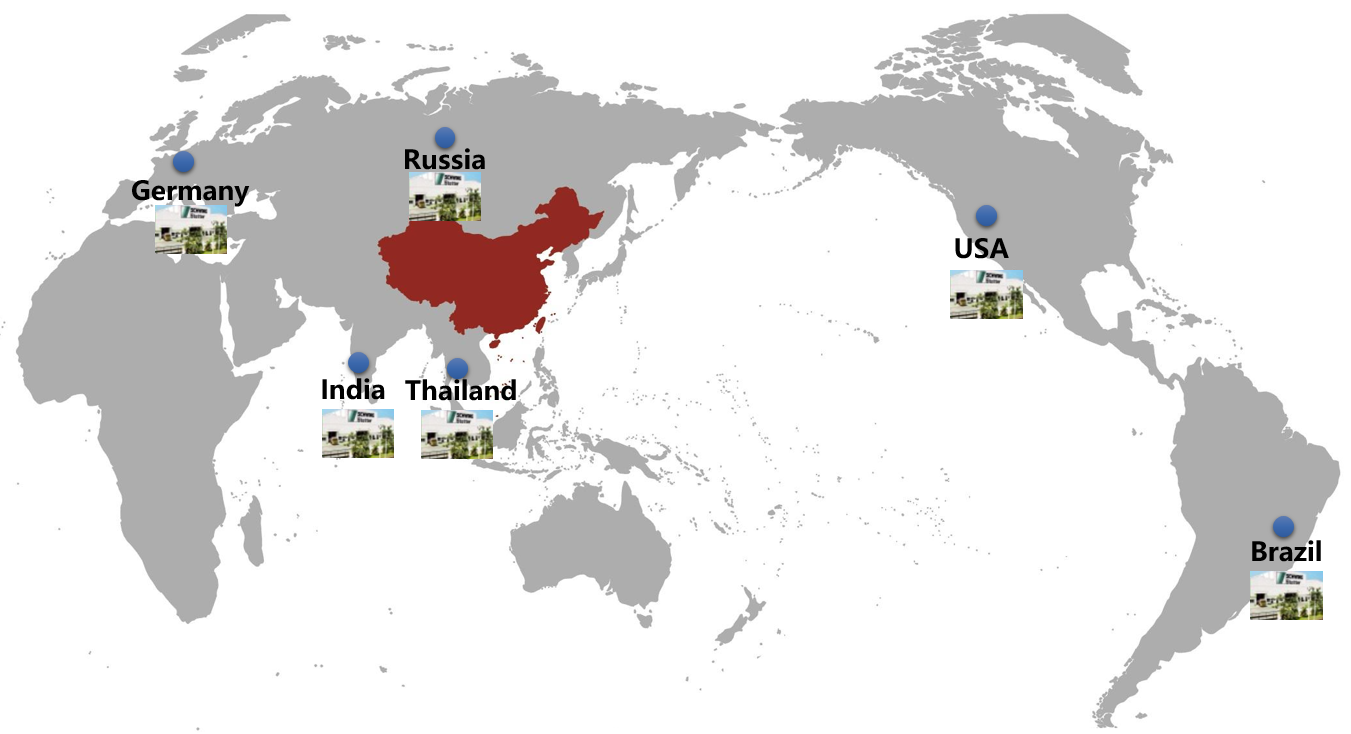

SALES AND SERVICE NETWORK

Q: Are you trading company or manufacturer ?

A: We are a manufacture located in Pingyang county Wenzhou city of Zhejiang province China

Q: How long is your delivery time?

A: Generally around two months, depends on the project and quantity.

Q: Do you provide samples ? is it free or extra ?

A: Sample is avaliable after all technical points are confirmed, sample fee and airfreight cost need to be invoiced in accordingly.

Q: What is your terms of payment ?

A: 40% T/T in advance ,balance before shippment.

Any further questions, pls feel free to contact us as below:

Contact person:Nancy Email:export@evergeardriving.com

Previous:

K series Spiral Bevel Gear Speed Reducer diesel engine speed reducer gearbox

Next:

R series in-line screw reducer for cement industry, screw reducer for sugar machine